Why is it that so few companies have an effective supply chain strategy? What we are going to cover today is how to put a plan together quickly and easily.

It can be frustrating, and I know that many businesses struggle to put a supply chain strategy together full stop. This article will show you how it can be such an easy thing to do once you remove all of the unnecessary complexity.

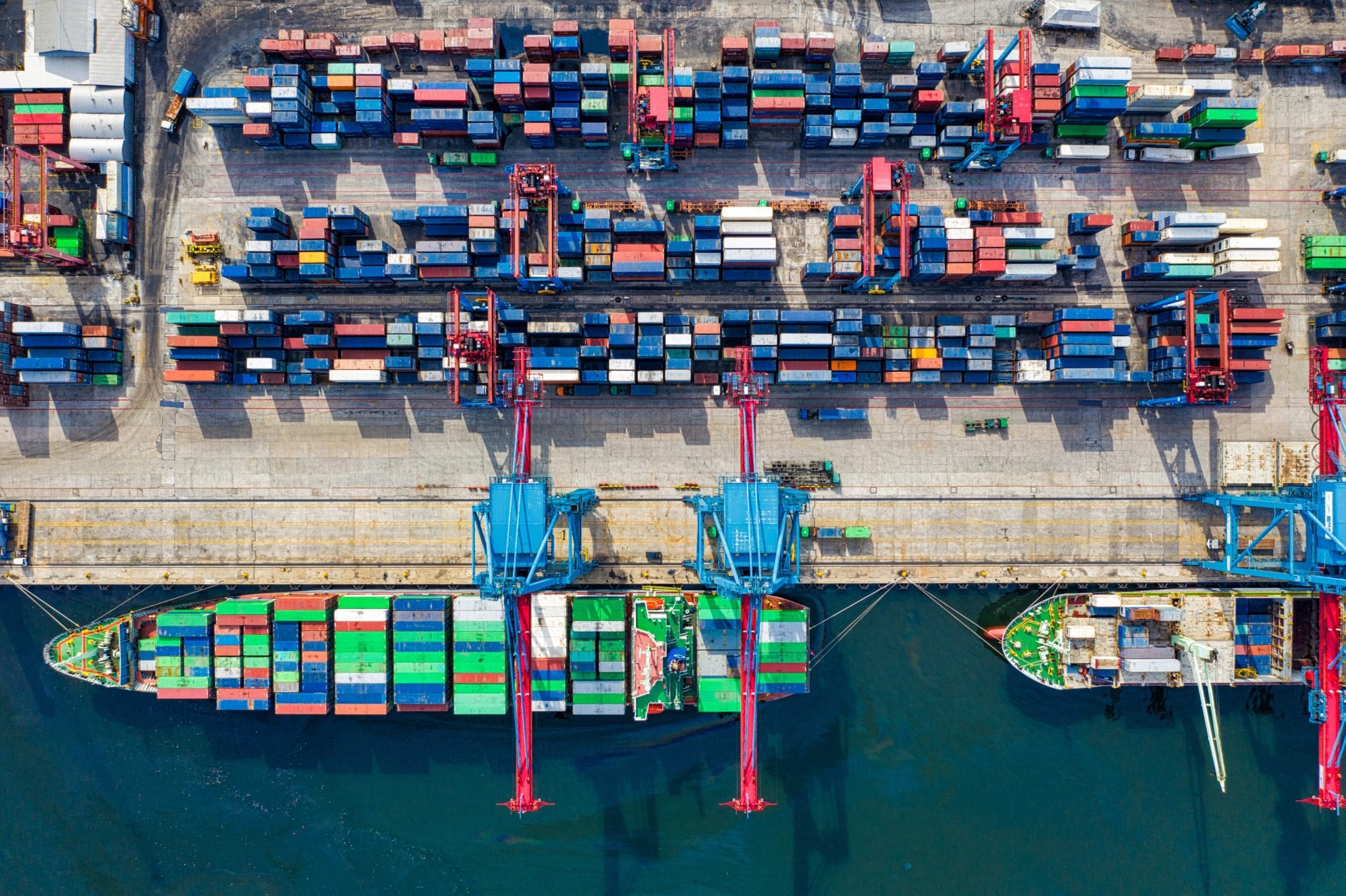

I’m sure you’ve all already seen this, but what I often see is that a company will have a great vision and mission. Their website will be beautifully curated, and you know very often there are images of impressive skylines or animated board room meetings or something like that. It’s all about the wonderful things they’re going to do in the world and the innovative products they’re bringing to the market. Unfortunately, all of that doesn’t necessarily translate down to the people who actually work within their supply chain and that’s where the disconnect occurs.

Here we’ve got a pack of wolves; they’re moving together as a group, in formation. It’s rather like the team of directors coming back from a big meeting where they’ve hammered out the goals for the business, and they know exactly what’s happening.

I suppose the question now is, does Joyce, the Warehouse Operative, understand what’s happening? That’s usually the most significant discontinuity in creating effective supply chain strategies. The people at the top develop the plan at the top, and it’s very theoretical and abstract. It’s, therefore, harder for people lower down in the business to understand how it is relevant to them.

Why Are Supply Chain Strategies More Important Than Ever?

Many businesses are losing money in the supply chain because they don’t have a strategy. According to a 2003 study, ‘The effect of supply chain glitches on shareholder wealth’ (Hendricks and Singhal, 2003), flaws in the supply chain caused an average fall of 10.28% in shareholder value. A plan is so essential to keep every department focused on doing their part correctly.

Interestingly, it took a global emergency to really bring the topic of supply chains to everyday people’s attention. The one positive thing to come out of a crisis is that it tends to focus us on the really important things. Almost every consumer now understands what it means if the supply chain is broken and how that impacts our day-to-day life.

Now the task is to make supply chains more resilient and more robust to change. On one side, you can build in redundancies; for example, don’t only source from one supplier. It’s also crucial to build business processes that are built for change.

It’s not necessarily that the global pandemic has changed the way that we function in terms of supply chains forever, but it has accelerated the evolutions that were already in progress. Such as the digitalisation of the supply chain and the focus on building a more resilient, agile supply chain that can react faster to change.

The Main Ingredients of an Effective Supply Chain Strategy

So, let’s keep it simple, let’s solve simple, essential things; otherwise, you will get left behind. Here are the critical components of an effective supply chain strategy. Below we have a diagram, and as you can see, the pieces overlap because it’s all about creating synchronicity between the industry sector, economic sector and consumer service sector.

If the strategy aligns with the industry and economic segments, we get optimistic investors. If we get the consumer service and economics coordination right, we get pleased customers. If we get the industry and consumer service coordination right, we get content employees because they know what they’re supposed to be doing each day.

There are also three things against each of these elements:

- Industry: In terms of the industry plan, we’ve got to have transparency around that. We’ve got to evolve it if it needs to grow, and we’ve got to constantly adapt and review to make sure that it’s working.

- Economics: Certainly, from a supply chain viewpoint, there are three main parts, storage, logistics, and acquisition.

- Consumer Service: The three parts here are having a reliable service and inventory policy and having a suitable planning procedure. Also ensuring that you have robust inventory management systems in place.

Honestly, we could probably break this diagram down into 100 different elements. However, I believe that this Venn diagram with nine parts around the outside keeps it simple and gets to the core of it. Ultimately if you get these things right, your supply chain will be in the top percentage of performers.

What Are Your Goals?

You have to start from the senior department level and work your way down. Come up with three simple goals for your supply chain, not ten, not twenty. Many supply chain strategies have tens of different parts to focus on, and it’s just too much. People can only focus on so many things successfully at once (Pillay, 2017), so three or four is the number that is both manageable and effective.

So how do you decide what those three goals will be for your business:

- What are the business’s goals?

- What are the business’s expectations of the supply chain?

Start with senior management and find out:

- What is the overall business strategy?

- What does senior management expect from the supply chain?

- What do they believe the supply chain performance is currently, and what would they like it to be?

Then once you have the answers to those questions, it’s not difficult to drop down a hierarchical level and see what the leading supply chain goals should be.

Generally, the primary goals are usually expenditure, standards and service. There’s also a fourth one in many industries, and that’s safety. So three or four goals should be sufficient for most businesses. The trick here is to successfully communicate these goals so that they’re significant to Joyce, who works on the assembly line in the warehouse. It shouldn’t be something too abstract or theoretical.

Let’s think about expenditure for a moment. What could we have as a simple goal around expenditure? It could be ‘Fully utilise space, minimise damage, decrease packaging’.

What could we have as a goal around service? Perhaps ‘Unify communications’. So think about that for a moment. What does that mean to people working in the supply chain? How could you articulate these goals to your different departments?

Coming up with catchphrases around the goals that explain the purpose behind them is essential for people throughout the organisation to fully understand. So step one is to come up with those three goals. Once you’ve done that, then we can start developing the methods.

How To Establish Effective Methods

When they first start to do this, some businesses think, “Oh, we need an automated warehouse management system,” or “we need a bigger warehouse”. Why? You need to work out your goals first, and then if those things directly support achieving those goals, they’re logical, but otherwise, they’re not. Remember, solve simple, essential things; otherwise, you will get left behind.

You’re essentially becoming more customer-centric as opposed to “What’s the challenge? Here are the solutions”. It forces you to think a bit more holistically about the entire market and the different channels at play.

The final thing once we’ve developed the methods is that we need to establish the metrics. So you don’t need tonnes of KPIs in your supply chain. You need maybe three under each of those goals. Let’s think about ‘Fully utilise space, minimise damage, decrease packaging’; what might be the KPIs we measure? If you’re an ecommerce business you’d be monitoring your availability in the warehouse, you’d be monitoring your supplier performance and delivery.

As you can see, it’s all synchronised. If we’ve got a goal of ”Fully utilise space, minimise damage, decrease packaging’, we need to have some enabling processes and technologies to ensure that we’re doing just that. We’ve got to measure the right things to ensure that we’re achieving those as well.

In conclusion, that is how simple it is to put an effective supply chain strategy together. It’s not difficult; you could sit down and brainstorm this right now. So I hope this has been helpful to you and shown you how not to let this process intimidate you. You are definitely more than capable of putting together a successful supply chain strategy.

References

Hendricks, K. and Singhal, V., 2003. The effect of supply chain glitches on shareholder wealth. [online] Wiley Online Library. Available at: https://onlinelibrary.wiley.com/doi/10.1016/j.jom.2003.02.003 [Accessed 30 April 2021].

Pillay, S., 2017. Your Brain Can Only Take So Much Focus. [online] Harvard Business Review. Available at: https://hbr.org/2017/05/your-brain-can-only-take-so-much-focus [Accessed 30 April 2021].

Fisk, T., 2019. Birds-Eye View Photo of Freight Containers. [image] Available at: https://www.pexels.com/photo/birds-eye-view-photo-of-freight-containers-2226458 [Accessed 30 April 2021].

Speak to 3PL about your eCommerce order fulfiment

It’s time to supercharge your ecommerce brand business and overtake your competitors. Speak to 3PL today and find out how we can take your ecommerce fulfilment to the next level.